PRODUCT

R Pump

With liquids of any viscosity and temperature,

which can be corrosive, abrasive and dangerous for the environment.

Used for transfer, dosing, processing, loading and unloading.

In chemical, ink, paint, construction, chocolate and oil-industry, in refineries and storage facilities

Description

OPERATING RANGE

With liquids of any viscosity and temperature, which can be corrosive, abrasive and dangerous for the environment.

Used for transfer, dosing, processing, loading and unloading.

In chemical, ink, paint, construction, chocolate and oil-industry, in refineries and storage facilities

Operating principle and limits of use

The R internal gear pumps are self-priming positive displacement rotary

The R internal gear pumps are self-priming positive displacement rotary

pumps perfect for viscous liquids (0,5 to over 500.000 mm²/s) of any

temperature (-60°C to 350°C), which can be corrosive, abrasive and

dangerous for the environment. The pumps are used for transfer, dosing,

processing, loading and unloading.

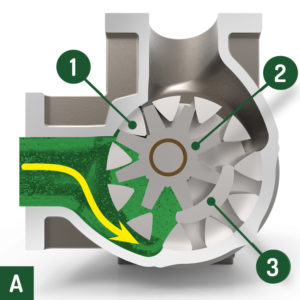

Two gears generate the flow: the rotor and the idler. The rotor moves the

internal idler. As the gears rotate, the liquid is drawn into the spaces

created between the gears and smoothly moved toward the discharge port,

where the divider , called crescent, closes the free space between the

two gears. When the gears mesh, the liquid is slowly forced out of the

pump. The result is a constant, smooth flow with no pulsations with a

capacity directly proportional to the rotation speed. This will avoid vibrations

on fittings, valves or couplings, reducing the foaming or churning of the

liquid.

The pump is equipped with one shaft seal or with magnetic coupling only,

and has the possibility of a heating jacket around the casing in one cast.

The full performance is available in either direction of rotation and the

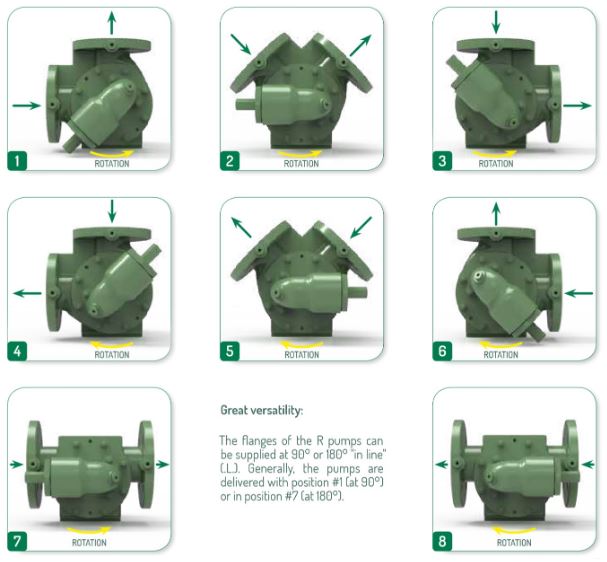

casing can be rotated and delivered with 90° or 180° (in-line) ports. A safety

relief valve against over-pressure is incorporated in the pump. This is a

heavy duty construction optimized for rare maintenance.

The pumps are available with ATEX certifications to fulfill the EU regulation

"Directive 2014/34/EU" that regulates the security of use for equipment in

potentially explosive atmospheres. We can supply ATEX certifications for

the areas of Group II, categories 2GD (Zone 1) and 3GD (Zone 2) for the

temperature classes T1/T2/T3 and T4. By filling out a simple

questionnaire, you can check the availability of the certificate for the

specific request. Further information is available on request.

ADVANTAGES

Self-priming.

The capacity is directly proportional to the rotation speed.

Non pulsating constant flow, therefore no vibrations on fittings, valves or couplings.

No foaming or churning of the liquid.

Only one shaft seal or with magnetic coupling.

Heating jacket around the casing in one cast.

Full performance is available in either direction of rotation.

The casing can be rotated and delivered with 90° or 180° (in-line) ports.

Relief valve against over-pressure incorporated in the pump.

Heavy-duty construction optimized for rare maintenance.

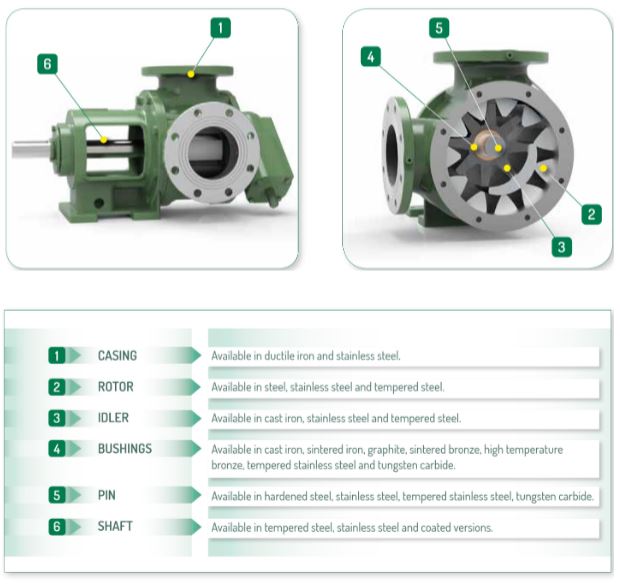

Materials and component section.

Orientation of suction and discharge flanges