PRODUCT

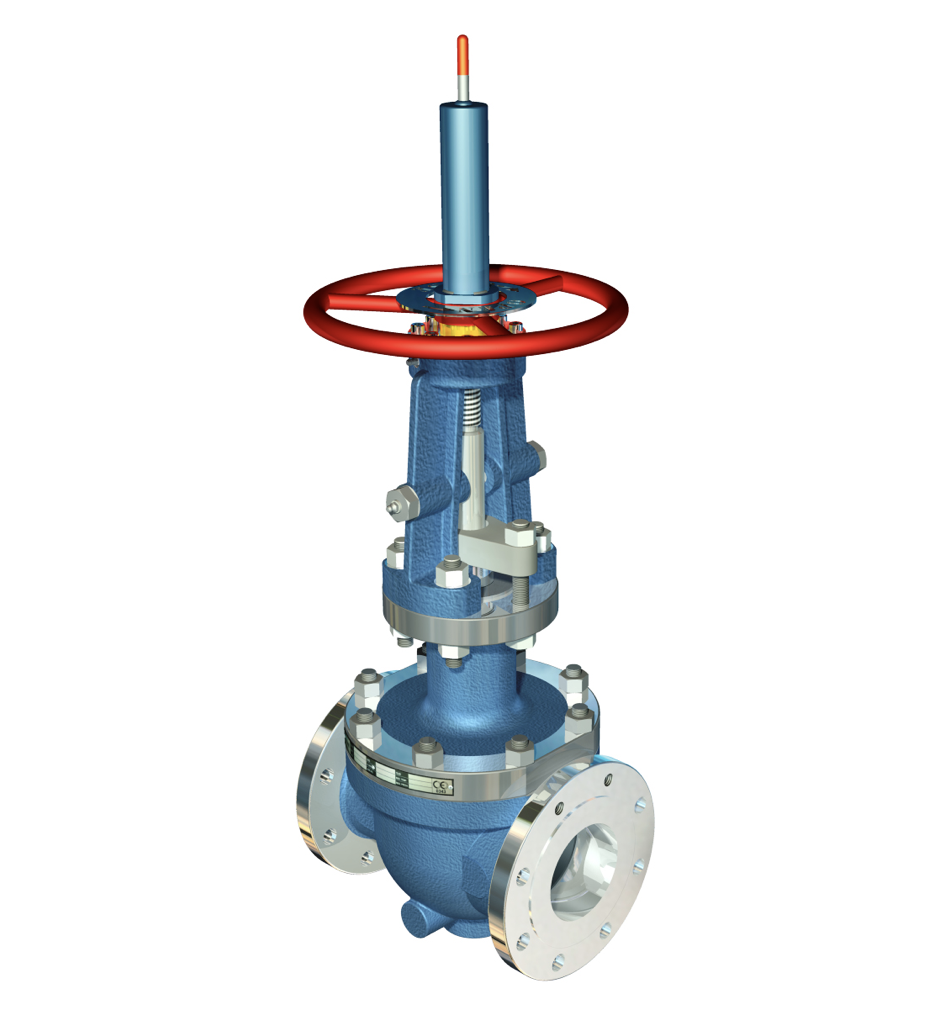

Non-Contact Rising Stem Ball Valve

Features Control Seal™ RSBV

Friction Free An important aspect of the lifetime of a valve is the sealing mechanism. Almost all valves, like Standard Ball, Gate, Plug and Butterfly valves have their sealing mechanism based upon shear force, friction and tearing. The Control Seal™ sealing mechanism is based upon axial movement only. The sealing is not liable to friction or tearing. This friction free quarter turn mechanical energised sealing does not generate abrasion on the seal and compared with other types of valves, it results in an exceptionally long lifetime.

Stem design The stem of the Control Seal™ Rising Stem Ball Valve makes only a small axial movement when opening or closing. The stem is always balanced NO stem rotation occurs in combination with axial movement when opening or closing.

Stem Packing The stem packing of the Control Seal™ Rising Stem Ball Valve can be adjusted while the valve is in service. All valves are executed with a back seat.

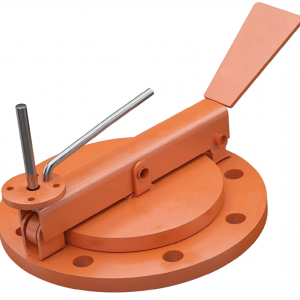

Inline maintenance and service As the Control Seal™ valve is designed for easy and low cost maintenance, top-access is possible while the valve is in-line.

Non-slam The self-locking operate mechanism on all Control Seal™ Valves, provides that the closing member can not rotate due to line forces, therefore there is no danger of line slam, shock or injury of personnel.

Fire Safe The Control Seal™ valves have been fire safe tested by independent laboratories and have passed the test to BS6755 part 2 and API 6FA successfully. These tests have been witnessed by Lloyds on several valves.

Description

Advantages of the Control Seal™ RSBV design

► Friction free opening and closing, increasing the lifetime of the valve.

► Single seat design, no thermal expansion problems.

► Corrosion and wear resistant materials are used on the closure members.

► Self cleaning closure members, due to high velocity flow during opening and closing.

► Top entry design for in-line inspection and maintenance.

► Adjustable stem packing while the valve is in service.

► All valves are executed with a back seat, which gives the possibility to renew the stem packing under pressure

► Mechanically energised sealing, no springs or other weak devices are required to obtain the sealing. ► Non lubricated seal.

► Pressure independent sealing.

► Stem moves only up and down, no rotation.

► No coupling cam in the stem construction

► Topworks according to ISO 5210

Materials Control Seal™ Rising Stem Ball valves can be supplied in a variety of materials and are also available in accordance with DIN standards.

Optional valve executions Control Seal™ can provide valves for various applications and services:

► Bellow sealed for dangerous media and zero emission.

► Stem extension for high temperature service.

► Stem extension and gas column for cryogenic service.

► Slurry and sand service (special design).

Rising Stem Ball Valve applications Rising Stem Ball Valves are often used in the following applications: Sand slurry service (special sand slurry design), Lethal (H2S) service (special Bellow Seal design), Produced water service, Steam service, Molecular Sieve service, Dehydration & Regeneration service, Hydrocarbon service, Gas metering, Emergency Blow Down and Shut Down service, Hot Oil service, High Temperature service, Low Temperature service.